In an age of resource depletion, global markets and climate change the stresses that have come to bear on industrial building practices are intense. No more so than when it comes to building insulation and the best way to achieve that. After all, it’s a building’s energy efficiency that will determine not only its carbon footprint but its operational cost as well. In this post we’re going to look at 5 common FAQs regarding industrial building insulation.

In an age of resource depletion, global markets and climate change the stresses that have come to bear on industrial building practices are intense. No more so than when it comes to building insulation and the best way to achieve that. After all, it’s a building’s energy efficiency that will determine not only its carbon footprint but its operational cost as well. In this post we’re going to look at 5 common FAQs regarding industrial building insulation.

Industrial Building Insulation: Common Questions

Let’s get right into it shall we?

- Can the facing of my insulation be painted? – Sure. You can paint the facing of your insulation, but why would you want to? In order to maximize the effectiveness of your insulation it should be sealed within the wall, not used as a finish element. Spend a few dollars more and get both a more appealing building and a higher degree of effectiveness from your insulation. Keep in mind too that painting the face may undermine its fire rating.

- Does fiberglass insulation get ruined if it gets wet? – If wet fiberglass insulation is allowed to fully dry and recover its thickness it’s possible it may recover its R-value. It is however, devilishly difficult to determine if the insulation has dried completely and, if there were contaminants in the water, these may also undermine the ability of the fiberglass to recover its R-value. As a general rule, fiberglass insulation that got wet during a flood should be replaced.

- What do I need to consider before insulating a metal building? – If your building is in a particularly damp location fiberglass may not be your best choice. The purpose of the building will also drive insulation considerations. If the building is occupied you’ll need plenty of first class insulation. If it’s just used to store construction equipment you can cut back on the insulation a bit.

- How should insulation materials be stored before using? – Leaving insulation lying around the jobsite while other processes are completed is never a great idea. Still, it happens. If it happens on your jobsite it’s essential that the insulation materials be stored in a safe, dry place. You should also avoid storing insulation directly on the ground or moving it too often since it can be compromised by repeated moving.

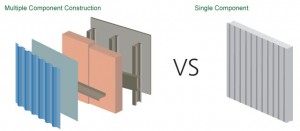

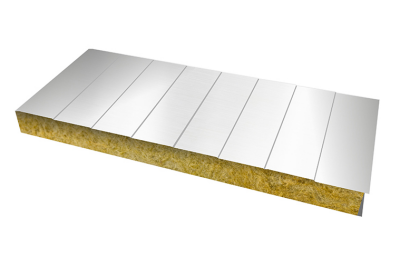

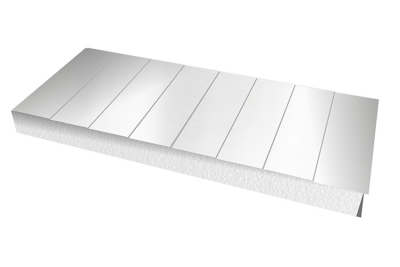

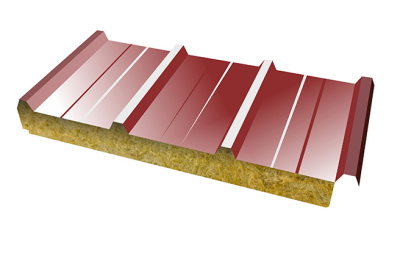

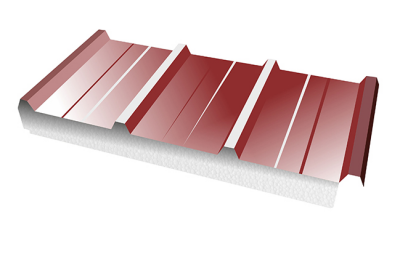

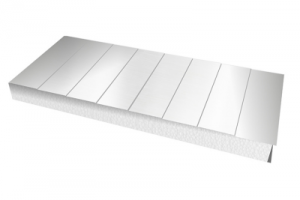

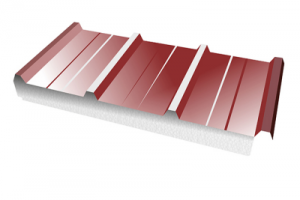

- What are metal insulated panels? – Until recently SOPs called for constructing a building’s shell and then filling that shell with insulation. Metal insulated panels however, allow you to eliminate several steps in the construction of your metal building, including having to add industrial building insulation after the fact. With metal insulated panels you simply lock them together using the groove joints and the assembled sections create a fully insulated, airtight envelope.

Industrial building insulation is one of the most important considerations you’ll need to weigh when planning your new building. When you use metal insulated panels from Eco-Insulated Panel Manufacturing solutions to complex issues of industrial insulation have already been engineered directly into the panels saving you time and money.

As much as 40% of your heating costs are associated in one way or another with your roof. This is due to the basic scientific fact that heat rises and so much of the heat you generate to warm the lower floors eventually winds up rising to and escaping through your roof. The rising of heat within the home creates a sort of chimney effect which draws more cold air into the house. The more heat that’s lost through the roof the more cold air gets pulled into the house, the more you’ll have to spend heating that cold air.

As much as 40% of your heating costs are associated in one way or another with your roof. This is due to the basic scientific fact that heat rises and so much of the heat you generate to warm the lower floors eventually winds up rising to and escaping through your roof. The rising of heat within the home creates a sort of chimney effect which draws more cold air into the house. The more heat that’s lost through the roof the more cold air gets pulled into the house, the more you’ll have to spend heating that cold air.