Metal panels are highly durable and can withstand harsh weather conditions, including heavy rain, strong winds, and extreme temperatures. Compared to other materials, they are less likely to crack, warp, or deteriorate over time, making them a long-term investment for industrial buildings. What are other metal roof benefits?

Low Maintenance

One of the major advantages of metal panels is their low maintenance requirements. They are resistant to pests, mold, and rot, requiring less frequent repairs and upkeep. In the long run, this can save both time and money, one of the best metal roof benefits.

Energy Efficiency

Metal panels can contribute to energy efficiency by reflecting solar radiation and reducing heat absorption. This helps to lower cooling costs, as the building stays cooler during hot weather. Some metal panels are also designed with insulation to improve energy efficiency further.

Fire Resistance

Metal panels are naturally fire-resistant, which makes them a safer choice for industrial buildings. They do not easily catch fire and can help prevent the spread of flames, providing an extra layer of protection for the building and its occupants.

Eco-Friendly

Many metal panels are made from recycled materials and are recyclable at the end of their lifespan. This makes them an environmentally friendly choice for construction, as they contribute to reducing landfill waste and conserving resources.

Aesthetic Versatility

Metal panels come in various styles, colors, and finishes, allowing for various design options. This versatility makes it easy to create a visually appealing industrial building that meets both functional and aesthetic needs.

Weather Resistance

Metal panels are highly resistant to weather conditions such as snow, ice, and heavy rain. They are designed to shed water effectively, reducing the risk of leaks and water damage. This weather resistance helps ensure the longevity of the building.

Quick Installation

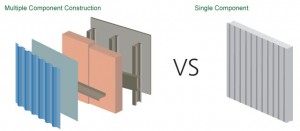

Metal panels are relatively easier and quicker to install than other roofing materials. This can reduce labor costs and construction time, allowing industrial buildings to be completed more efficiently.

Lightweight

Metal panels are lightweight compared to traditional materials like concrete or tile. This reduces the building’s structure load and can lead to cost savings regarding foundation and support requirements.

Structural Strength

Despite their lightweight nature, metal panels offer excellent structural strength. They can support heavy loads and resist impacts, making them suitable for highly demanding industrial environments.

Cost-Effective

While the initial cost of metal panels may be higher than some other materials, their durability, low maintenance, and energy efficiency often result in cost savings over time. This makes them a cost-effective choice for industrial buildings in the long run.

Contact Us Today

Looking for top-quality metal roofing and metal panels? Look no further than Eco-Insulated Panels. Our expert team specializes in durable, energy-efficient, and eco-friendly metal panels that offer numerous benefits, including weather resistance, fire resistance, and cost-effectiveness.

With a wide range of styles, colors, and finishes available, we can help you achieve both functional and aesthetic excellence. Contact our expert team today to discuss your specific needs and benefit from quick installation, structural strength, and long-term cost savings. Elevate your home or industrial building with our superior metal panels. Contact us now for a consultation!