If your home or building is constructed using insulated panels, you may be wondering why all buildings aren’t constructed this way. Insulated panels create homes and structures that are durable and energy efficient. And once the siding is installed, it is impossible to differentiate a house constructed from IMPs with a conventional one. But are these panels quicker for construction than their timber counterparts?

The Answer Is Yes!

Homes using insulated panels can be constructed considerably quicker than traditionally framed buildings. A properly trained Structural Insulated Panels (SIP) installation crew can cut framing time by as much as 55%! But what makes construction with these panels so much quicker?

What Is A SIP?

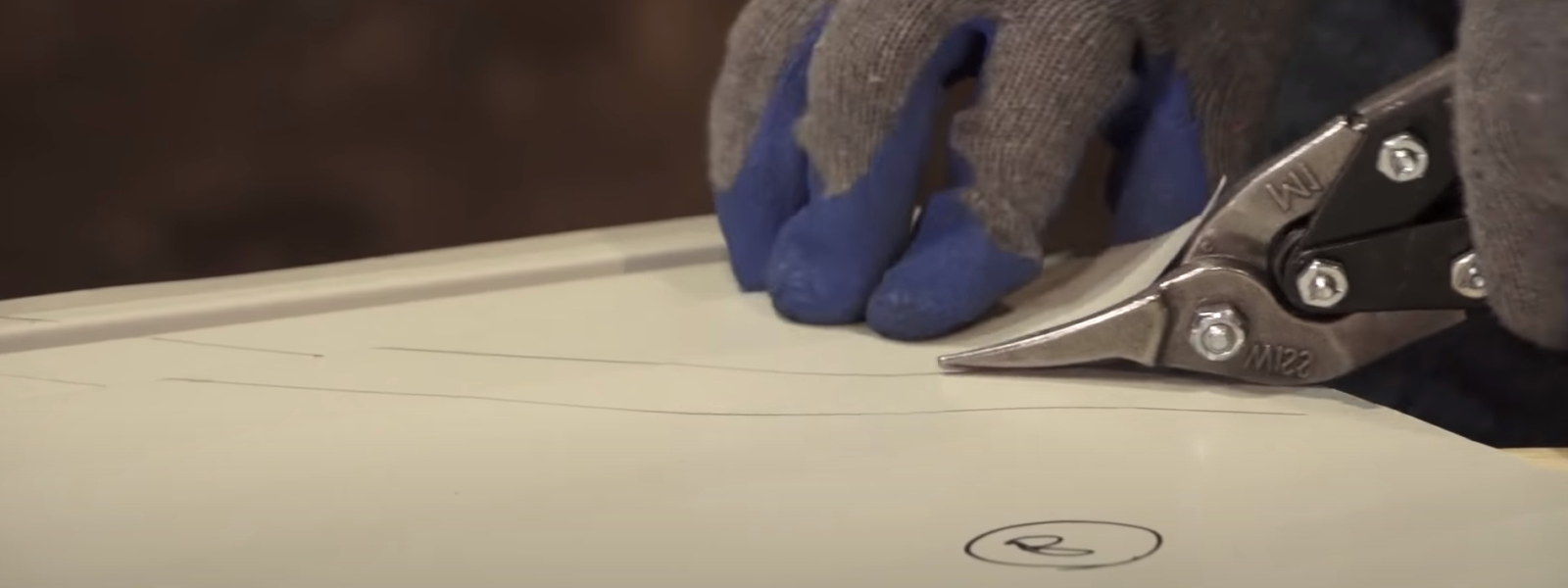

SIPs are an advanced method of construction consisting of an insulating foam core, sandwiched between two structural facings. This kind of panel can be used for walls, roofing and floors. Because these panels are pre-manufactured and easy to erect, construction time is drastically reduced.

7-Day Build

When using SIPS, construction of a typical two-story home will take between five and seven days. This is because SIPs are pre-manufactured to your own requirements. This saves both builders and architects a lot of time on site, while further reducing the number of materials needed for a similar size build. Simply slot the panels together on site and voila! And because less supporting structure is needed, these panels also allow for a more open floor plan.

SIP Flooring?

Yep, these panels can also be used for flooring. They are even designed with the ability for utilities to run through them, meaning no drilling. If aesthetic is a concern, fear not. These panels range in style from metal to timber. And the best part? This flooring can be installed in a matter of hours opposed to the 3 days conventional flooring takes.

It’s not just construction time you can save when building with insulated panels. Builders will also enjoy decreased construction and labor costs, while homeowners will enjoy continuous insulation and better control over air quality. Wondering if insulated panels are right for you? Our qualified team of professionals would be happy to help you! Contact us today at 519-451-7663 or info@ecoinsulatedpanels.com.